Loading Files...

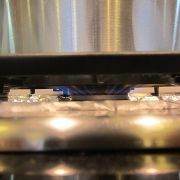

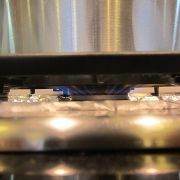

Mash at 157F for an hour.

Boiling the wort with hops.

Sanitize the chiller and spoon in boiling wort.

Sanitize the fermentation bucket and equipment in iodine.

Chill the boiled wort back down to about 70F.

Chilled wort ... but not beer yet.

Strained out the hops, poured into a bucket, and sprinkled yeast on top.

Into the fermentation chamber at 65F for a week or two...

Two weeks later ... time to keg it. This is my kegging equipment.

First, sanitize the keg. I use an acid rinse sanitizer this time ... which foams a lot.

After two weeks of fermentation at 65F.

Yes, you're going to drink this.

Rube Goldberg, but functional... siphoning the beer into the keg without adding much oxygen at this point.

To the left, autosiphon. To the right, a picnic tap running backwards.

The first glass of flat, green and rather warm stout. It actually tasted not bad, which is a good sign at this stage.

The yeast and proteins that sank to the bottom of the fermenter begin to appear.

Keg is almost done filling, and some of the sanitizer foam has started to come out.

Beer has been transferred ... leaving a moonscape.

Now - pressurize the keg with CO2.

Ready for aging at room temperature for a month or two...